2020 was a doozy of a year, and now more than ever, we know the importance of working together and building a strong network of community and support, so that we can all succeed. With that in mind, we have invited some of our respected colleagues to write guest posts for our blog. With most professions, as soon as you start scratching the surface about what they do, you start to realize how much more they are responsible for to do their job than you even realized.

Electrical engineers design systems to make sure we have the right amount of power to do what we need and that it is all safe. Most of us are familiar with single phase power that serves homes and many businesses. CE Engineers deals a lot with three phase power, which provides much higher current and is typically found at large buildings and industrial sites. Here’s a peek into their world of expertise!

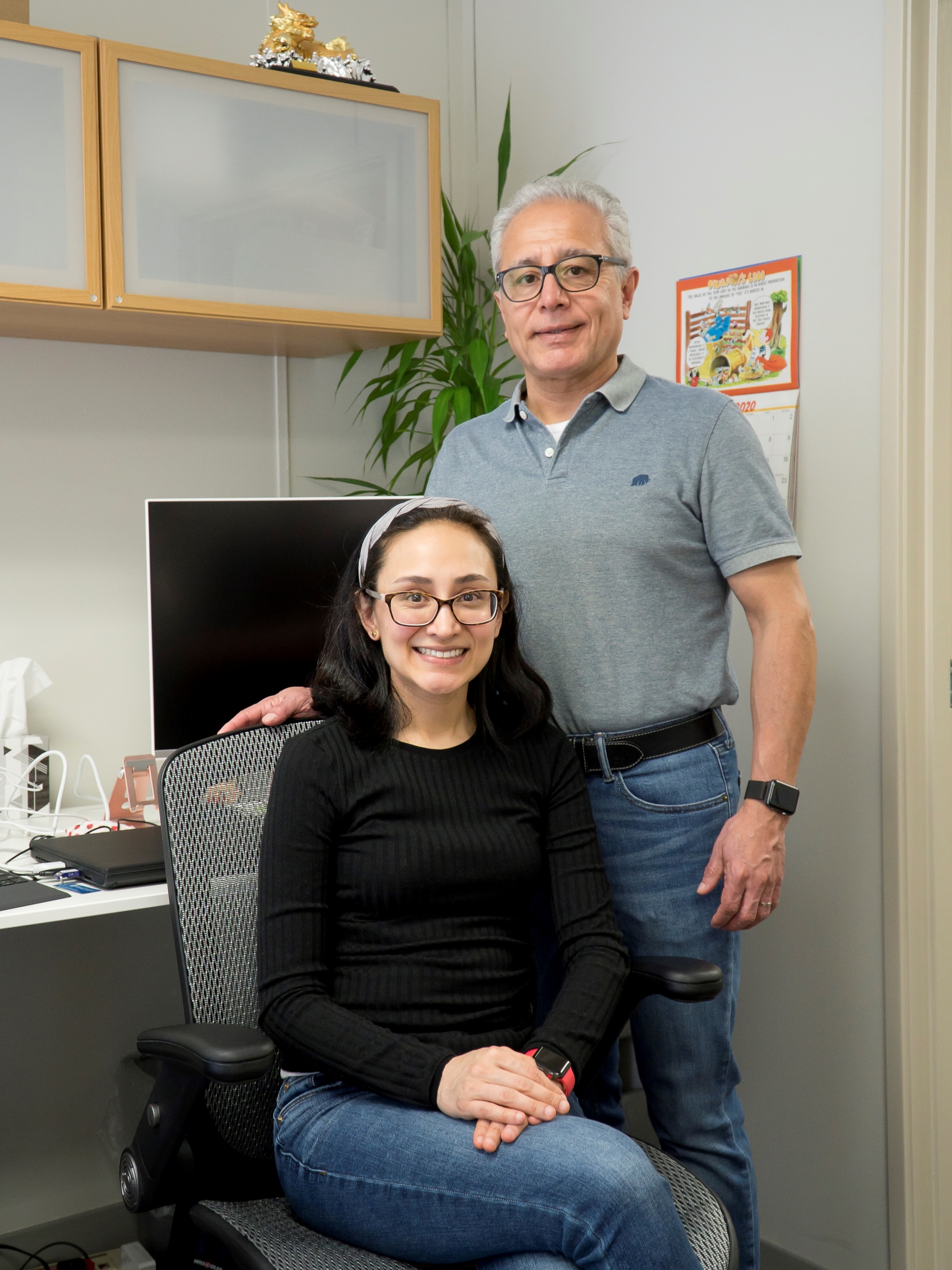

Written by Diana Delgado

Hello! I am Diana Delgado part owner of CE Engineers. CE Engineers is a father-daughter owned Electrical Engineering firm based in Portland, Oregon. Electrical engineering is a very broad field, but we specialize in Electrical Power Distribution Design, Power Studies for Facilities (Arc Flash Studies, Short Circuit Studies, Protective Device Coordination, etc.) and Controls and Instrumentation Engineering.

Out of all the services we provide arc flash studies are my favorite. It’s easy to take a facility’s electrical system for granted, and typically it is not replaced until something goes wrong. We come across sites where the building has been remodeled or renovated several times over the past 2-4 decades, but the main distribution board and panels remain original to the facility (over 30+ years old). This always amazes me since we rely so heavily on electricity to power our lights, computers, phones, HVAC units, data centers, etc. If a main electrical component stops working, a site or part of the site can be out of service for several hours if not days. In the process of performing an arc flash study we get to analyze the electrical system of a facility and find any deficiencies and help come up with solutions.

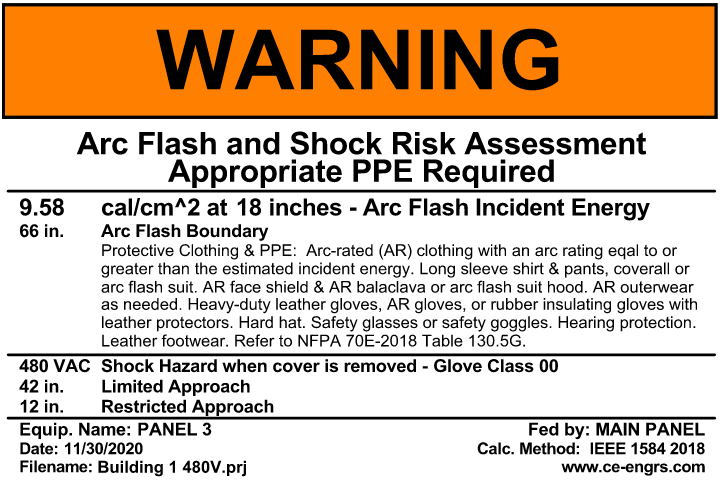

What exactly is an arc flash study and why is it important? To answer that let’s start with defining an arc flash – an arc flash is an electrical explosion created when an arcing fault occurs between electrical conductors. This electrical explosion can be deadly in high current systems to electrical personnel servicing electrical equipment especially if they are not wearing the proper personal protective equipment (PPE). How do personnel know what PPE to wear? By looking at the arc flash label on that equipment.

This arc flash label is the result of an arc flash study done at the facility. The arc flash study provides a plethora of information which we will get into a bit later, but the most important product of the study are arc flash labels that indicate how severe the hazard is at any panel, disconnect, switchboard, or motor control center that is greater than 208VAC at commercial or industrial sites (examples of common equipment that use this voltage would be fans or HVAC units at commercial and industrial sites). The hazard is shown as incident energy, which is a measurement of heat as a function of distance and time. The incident energy on the label dictates what level of PPE is needed to provide workers with protection from an arc flash at each piece of equipment.

An arc flash can be caused in a variety of ways such as human error (accidental touching or dropping of tools), material failure, dust, poor maintenance, age, faulty installation, or condensation. A lot of the causes can be avoided by providing regular maintenance to electrical equipment and replacing old electrical equipment before it malfunctions.

To perform an arc flash study, we must first create an accurate one-line diagram (map) of the electrical system and collect accurate electrical equipment data (such as breaker types, sizes, settings, fuse information, conductor type, transformer nameplates, etc.). We then use special software to model the electrical system and run the analysis. This includes a short circuit analysis, an arc fault analysis and protective device coordination. We evaluate all results, create a report, review the report with the customer and provide arc flash labels. Some common issues we find are equipment that is not sized properly, underrated equipment, or breaker trip setting issues.

To summarize, the benefits in having a study done are: #1 the safety for personnel as well as code compliance, identification of electrical system issues, increased reliability of the electrical system, updated one-line diagram, and inventory of electrical equipment.

Arc flash studies allow us to educate our customers on their electrical system, help them make it safer for their personnel and improve it, which is why it is one of my favorite services we provide.