Written by Adam Robins

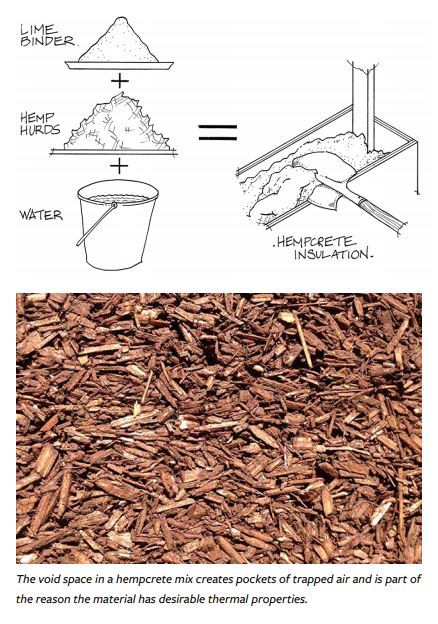

Hempcrete, or hemp-lime, is a building insulation material made of hemp bio-fiber (often called hemp hurd or shiv), water, and lime. Blended together, the lime coats all parts of the shiv and is activated by the water, resulting in a chemical bonding reaction. Theoretically, many types of cellulose fiber could be used, but hemp has some advantages over lots of other potential choices, prominent among them being that hemp grows quickly and easily and has very strong fibers.

Image sourced from: Essential Hempcrete Construction by Chris Magwood

Hemp, being essentially a different strain of the same cannabis sativa that is only legal in certain jurisdictions, but it doesn’t have the psychoactive capabilities of that one that people will line up at shops to buy. Industrial hemp was only legalized finally in the 2018 Farm Bill in the United States, so a lot of what has been done with industrial hemp up until now has taken place in the shadow of an 80-year prohibition.

Click here to watch a short video of hemp being harvested.

But why would someone want to build with hemp? Well, there are some advantages.

- Hempcrete is a nontoxic material, and so those with sensitivities to VOCs or off-gassing from synthetic materials can avoid such exposures.

- Hempcrete has thermal performance benefits, acting as both insulation and as thermal mass. The air pockets give it insulating qualities, and the density of the lime binder gives it the thermal mass. This allows hempcrete to act as something of a thermal “battery,” storing heat when the ambient air is warm and releasing it back when the ambient temperatures drop.

- Hempcrete can help spark new industries including growing, processing, construction, and installation. Hempcrete is a possibility for economically depressed areas to jump-start employment and provide both a local resource and an industry that could bring money from surrounding areas.

As with any building material, there are code considerations. Hempcrete, being essentially recently legalized and being relatively new, is not in either of the more popular building codes in the U.S., the International Residential Code (IRC) or the International Building Code (IBC).

Fortunately, building codes include provisions for considering other materials. Usually, the applicant must show that the performance criteria for the building are being met by that material are being met, things like structural performance, thermal performance, and fire resistance.

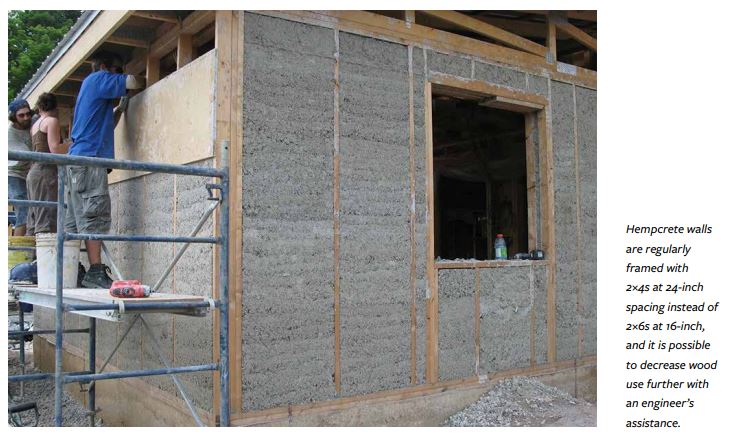

Structural is easily handled in a framed structure with hempcrete in the spaces between the framing. Lots of code language is written for framed structures and it is very likely a prescriptive path or engineered wooden structure would be permitted without much hassle.

Image sourced from: Essential Hempcrete Construction by Chris Magwood

For other considerations, it is incumbent upon the applicant to furnish supporting documents. These can vary by jurisdiction and even by plans examiner, but by addressing the concerns in an affirmative manner can go a long way toward winning approval. Some possible items that may help this are:

- Examples of past performance: This could include prior case studies or examples, with previously approved projects in the same jurisdiction often being the most convincing.

- Testing: Data from tests, particularly independent tests performed using code-recognized standards like ASTM.

- A/E stamps: Design professionals’ stamps carry weight.

Other practical concerns beyond the strictly code related would include acoustics and moisture.

A separation wall between units consisting of two 6” hempcrete walls with a 3” space between then was tested in the UK offering a sound reduction of 57 to 58 dB between units.

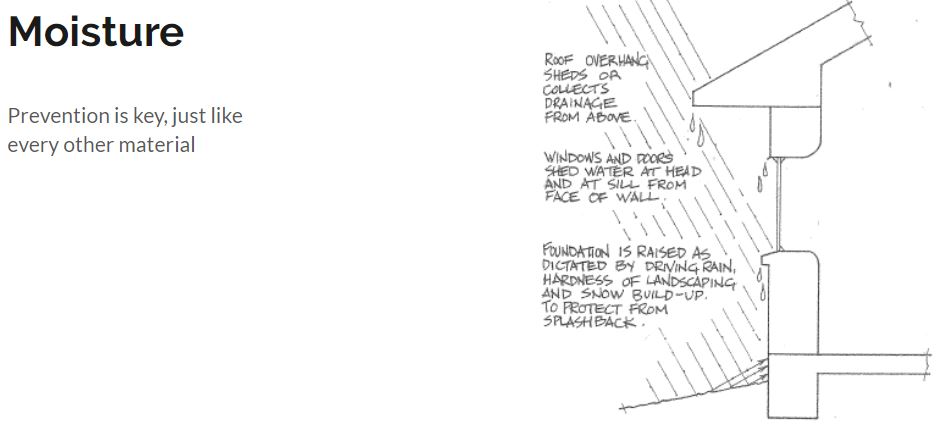

Image sourced from: Essential Hempcrete Construction by Chris Magwood

Moisture is handled a bit differently than the current focus on vapor barrier systems. Hempcrete can maintain its integrity with some moisture content, and hemp hurds are able to contain a lot of moisture during humid conditions and release it when it is drier. The lime in hempcrete is inherently mold-resistant even when temperature and humidity would encourage mold in other insulation materials. For this reason, a hempcrete wall assembly needs to be allowed to breathe.

Much more work has been done with hemp in other countries that have not shared the same tight restrictions on industrial hemp. For more code-approved structures to be built with hempcrete, it’s going to take a lift of many things all at once, from more independent lab tests and more industry standards and more case studies and built history. It’s a lot of things that have to happen together to make hempcrete more mainstream, but that’s what it can take after an 80-year ban.

Further reading:

- The Hempcrete Book: Designing and Building with Hemp-Lime by William Stanwix and Alex Sparrow

- Essential Hempcrete Construction by Chris Magwood

Placecraft provides alternative construction and is located right here in our neighborhood. If you have an idea for a project and are looking for a builder, we recommend reaching out to them!